Vari-Stem® Stemming plugs

Origin: USA

Blast energy can be divided into two components:

Applied energy – shock & heave energy used in material breakage;

Lost energy – manifests itself as air over-pressure, ground vibration & excess fines (over-blasted material).

Stemming is inert material used to confine energy in the blast hole at the top of the explosive charge. Insufficient or inefficient stemming allows the blast energy to prematurely vent at the collar, reducing the energy applied to breaking & moving the rock mass. Stemming ejection is a common cause of lost energy in the blast, especially when drill cuttings are used.

Oresome Products are proud to be the exclusive distributor for Vari-Stem® in Australia & the Oceania region. The Vari-Stem® plug is patented & proven technology deployed globally in mining & quarrying applications to maximise applied energy. Vari-Stem® reduces processing costs by achieving tangible increases in fragmentation in the stemming area. Independent studies show the Vari-Stem® plug can increase blast patterns with the same fragmentation for major savings in drilling and explosive costs, proving that Vari-Stem® plug is a cost-efficient means of reducing costs in blasting and processing. Case studies can be found at www.varistem.com.

Installation & use of Vari-Stem® stemming plug to increase blast energy confinement

FEATURES

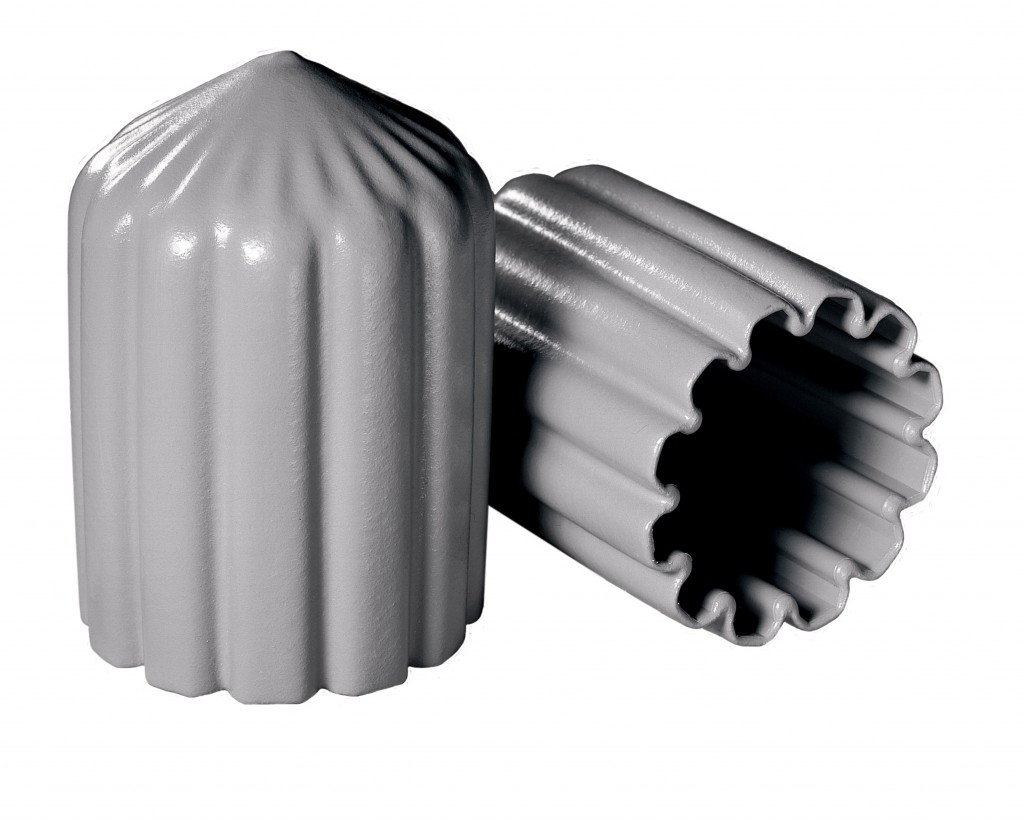

- Sized for Ø32 to 251mm blast hole diameter (other hole sizes on application).

- Tough moulded PVC material.

- Tactile outer surface for superior grip onto blast hole wall

- ‘Gear-profile’ to protect down lines & cords and facilitates water displacement in wet holes

- Can be used in open pit and underground mining applications

BENEFITS

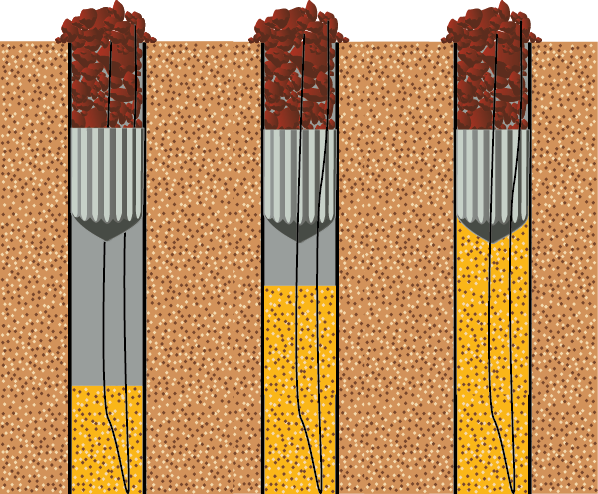

- Increases the effectiveness of drill cutting stemming material by increasing ejection resistance

- Stemming time to movement in the blast can be doubled

- Stemming ejection velocity in the blast can be halved

- Prevents explosive emulsion dilution by stemming material that can affect energy performance

- Increases rock fragmentation, especially in the cap rock area through improved confinement

- Improves total mining productivity (dig, haul & processing)

- Decrease total cost of mining through energy savings & productivity gains

- Reduces fly rock & air blast through improved confinement

- Simple installation requiring little operator training or skill

RANGE

| Part# | Description | Bit size (mm) | QTY/box |

| 3-9396 | BP-2 Vari-Stem* | 51 | 210 |

| 3-9394 | BP-2.5 Vari-Stem* | 64 | 144 |

| 3-9393 | BP-3 Vari-Stem | 76 | 160 |

| 3-9395 | BP-3.5 Vari-Stem | 89 | 96 |

| 3-9392 | BP-4 Vari-Stem | 102 | 84 |

| 3-9402 | BP-4.5 Vari-Stem | 115 | 81 |

| 3-9426 | BP-5 Vari-Stem | 127 | 48 |

| 3-9427 | BP-5.5 Vari-Stem | 140 | 48 |

| 3-9428 | BP-6 Vari-Stem* | 152 | 30 |

| 3-9418 | BP-6.5 Vari-Stem | 165 | 21 |

| 3-9425 | BP-7 Vari-Stem | 177 | 18 |

| 3-C6112-8 | BP-8 Vari-Stem | 200 | 15 |

| 3-C6112-9 | BP-9 Vari-Stem* | 229 | 3 |

| 3-C6112-10 | BP-10 Vari-Stem plug* | 251 | 15 |

Loading Poles

Origin: Australia using USA components

The loading pole is Ø30mm x 1.8m straight grain Tasmanian Oak wooden pole used for placing stemming plugs and compacting back-fill to lock the plug in blast holes. The aluminum Ø5/8″ threaded connections (male & female) may be coupled together with matching threaded ends to extend your loading poles. The rubber plug is made of durable rubber and has Ø5/8″ male threaded connection. Available in custom lengths – please ask for details.

Saver Plug

Origin: South Africa

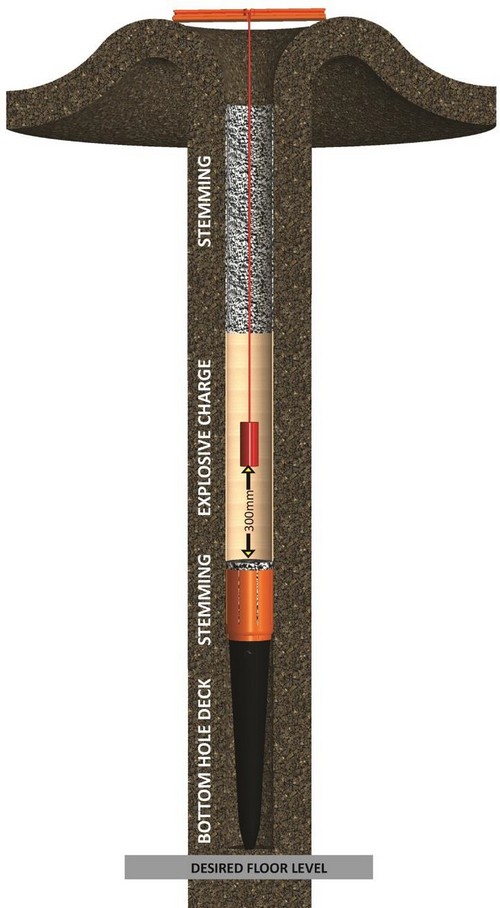

Saver Plug, used to create a bottom deck, can result in reductions in flyrock, vibration, drilling costs, and the volume of explosives used in some geologies. It can also double as a demarcation product prior to deployment down the hole.

Saver Plug can be used in conventional blasting operations and casting applications. The Saver Plug creates a void at the bottom of the blast hole that when the hole is initiated, a pressure pulse will be directed into the void beneath the Saver Plug followed by the high pressure gas front.

It has also been proven that by focusing some of the blast energy in a downward direction, an increase in control is possible. In some cases, stemming length can be reduced without increasing the danger of fly rock. Sub-drill can be reduced or eliminated, and in casting applications the throw volume can be increased.

When an explosive detonates in a borehole, the high temperature by-products of the detonation will always take the path of least resistance. The bottom hole deck will first be subjected to an intense shock wave. After the initial shock wave front hits the bottom of the hole it creates a reflection and increases the pressure at that point.

As the reflection occurs, a separate secondary impact from the explosion products adds another pulse to the bottom of the hole. The combined effect is that the resulting pressure at the bottom of the hole can be increased greater than the initial pressure, and may be sufficient to create a planar split and fragmentation.

Theoretically, the sum of the primary shock wave energy and secondary explosion products are far more efficient than a concentrated cylindrical charge when the bottom hole air deck length and plug mass are properly designed for the specific conditions and explosives used.

By simply filling the pre-assembled Saver Plug with stemming material (crushed rock is optimal) and dropping to the base of the bore hole you create a path of least resistance for the explosive energy to seek.

| BIT Ø | MODEL | |||

| 127 | 140 | 171 | 311 | |

| 115 | ▲ | |||

| 121 | ▲ | |||

| 125 | ▲ | |||

| 127 | ▲ | |||

| 141 | ▲ | |||

| 151 | ▲ | |||

| 165 | ▲ | |||

| 171 | ▲ | |||

| 200 | ▲ | |||

| 229 | ▲ | |||

| 250 | ▲ | |||

| 254 | ▲ | |||

| 270 | ▲ | |||

| 311 | ▲ |

SNAPPER non-aerosol gasbag

Origin: Australia

Oresome Products proudly represent the Mintech gasbags in designated markets.

Mintech are pioneers in the patented development and manufacture of Aerosol and Non-Aerosol Gasbags, with manufacturing based in Australia. Mintech gasbags are designed for a variety of blasting applications, including hazardous underground environments.

Oresome Products have vast experience in the Mintech non-aerosol gasbags known colloquially as the Snapper range. The Snapper gasbags supplied by us are:

- Non-toxic (both in terms of ingredients & gas produced) – unparalleled operator safety

- Non-flammable inflation gas (CO2) – no possibility of in-hole ignition

- Entirely non-metallic/ferrous – downstream contamination mitigation

- Ingredients are food-grade lemon juice & bicarbonate of soda

- Are not classified as a dangerous good for transport, storage or use – lower shipping & storage costs

- Contain no stored energy – providing unparalleled safety in hot environments

Drill Hole Saver Plugs

Origin: Canada

FEATURES & BENEFITS

Drill hole saver plugs (or collar cones as they can be known) are being recognized as important tool in drill & blast operations. Hole plugs prevent unintended back-filling of the drilled blast hole with drill cuttings and prevent ingress of other surface matter and fauna entering and contaminating the hole prior to charging. Heavy mud slime at the bottom of the hole can dilute and corrupt explosive products, causing low order detonation that can result in toe, fume, or even misfire. It can be shown that these prevention benefits far exceed the life-cycle cost of hole plugs. Hole plugs can also maintain the integrity of the collar through erosion prevention, particularly in high rainfall areas.

| Part# | Description |

| 3-0900A BOX | Hole Saver – 32-50mm hole saver (ABAQ HPA) – 250 per box |

| 3-0900B BOX | Hole Saver – 64-89mm hole saver (ABAQ HPB) – 125 per box |

| 3-0900C BOX | Hole Saver – 89-150mm hole saver (ABAQ HPC) – 50 per box |

| 3-09008 BOX | Hole Saver – 89-203mm hole saver (#8 Sombrero) – 25 per box |

- Superior quality injection moulded construction, for strong, stable design.

- Zero-percent recycled LDPE plastic resin for enhanced operating temperature capability.

- Sizes align to standard drill bit diameters, ranging from Ø32mm to Ø325mm to cover virtually every mining & quarrying application

- Down-line clips integrated into the design of the rim, for greater security and loss mitigation

BOMB Condom™ LINER RANGE

Origin: Australia

The BOMB Condom™ range of lining products are made in Australia for tough mining conditions anywhere. BOMB Condom™ liners feature internal low slip & anti-static treatment and UV stability. BOMB Condom™ is a mono-film extrusion for high flexibility and strength.

FEATURES

- Sizes: 45mm, 51mm, 64mm, 76mm, 89mm, 102mm & 115mm (others on application).

- Tough, flexible and lightweight anti-static treated material.

- 250um thickness extruded mono-film, 200m roll length.

- Printed with hole size every 1 metre.

- Complies with AS 2187.2:2008.

BENEFITS

- Prevent explosive desensitization by the presence of water, especially dynamic ground water.

- Contain the explosive product within the blast hole in fractured ground, ensuring complete decomposition during detonation.

- Provide physical separation between the explosive product & reactive soil types.

- Allows the use of ANFO when water resistant explosive is unavailable, uneconomic, or both.